Drying Information

FALL ADDITION OF SUPPLEMENTAL HEAT

Is adding supplemental heat right for my farm? In the field of natural air drying, the question often comes up as to whether or not adding supplemental heat to a natural air drying system will be beneficial. To answer this question, you must first assess your environmental conditions, as well as, your natural air drying equipment. If you are dealing with low ambient air temperatures and/or high relative humidity (RH), then yes, adding supplemental heat to your natural air drying system will be of benefit. If you have aeration fans and equipment in place to provide 0.75 to 1 cfm per bushel, then adding supplemental heat will also be beneficial

SPRING GRAIN STORAGE MANAGEMENT

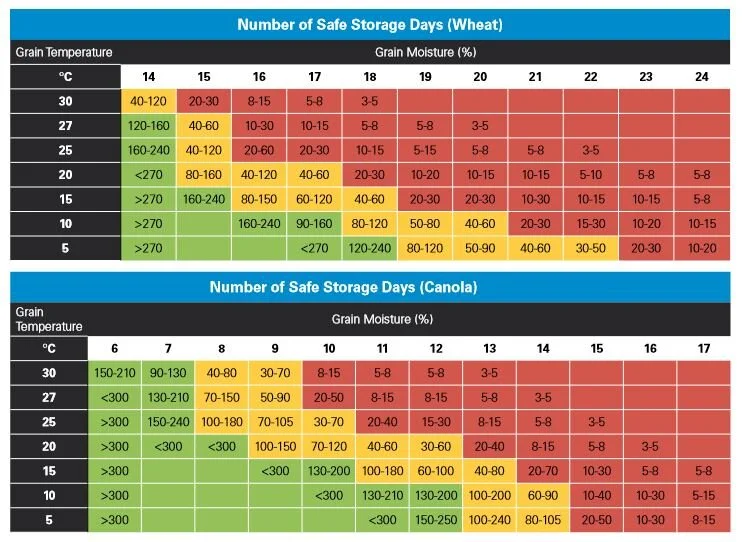

In circumstances where you need to warm grain to finish drying in springtime conditions, it is recommended that the temperature be brought back up gradually. This will help preserve the quality of the grain kernel. Once the grain has been successfully dried, it is recommended that when possible the grain be cooled again to be stored at approximately 10°C. In summary, monitoring moisture and temperature conditions in your bin, and having an aeration system in place to help regulate these conditions, is key to successful grain storage.

Summer Drying

SUMMER AERATION VS NATURAL AIR DRYING

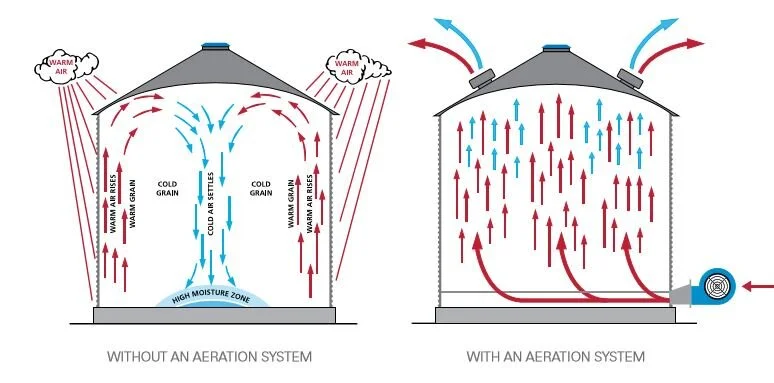

Grain conditioning is a widely used term that can be used to identify situations where either aeration or natural air drying is being utilized. Knowing the difference between aeration and natural air drying will aid in selecting aeration systems, equipment, and storage that will best suit your needs.

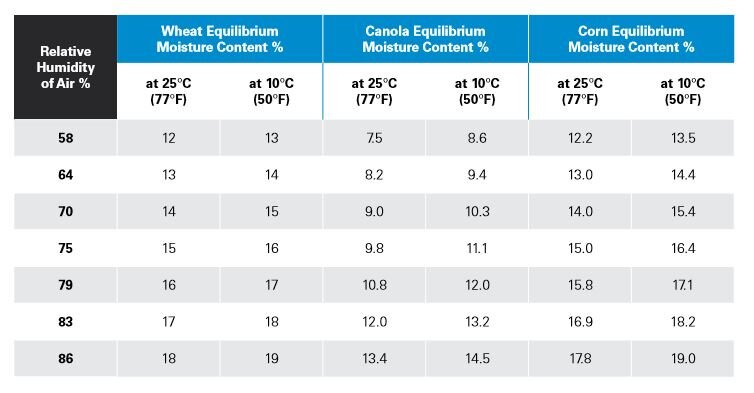

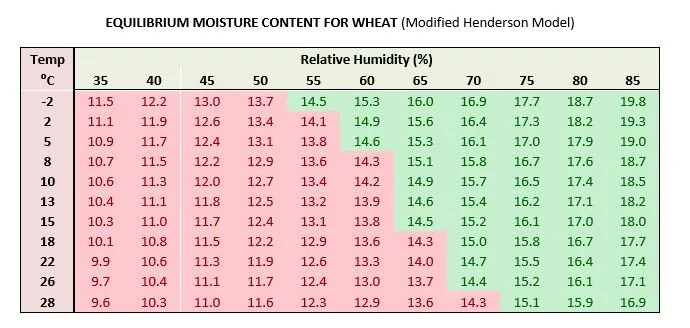

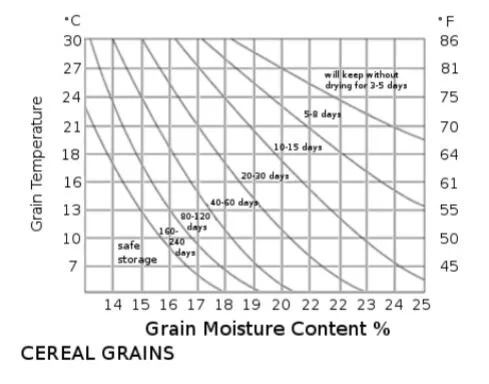

PAMI EMC Charts

The equilibrium moisture content (EMC) of air can be used to predict how the ambient air will affect the moisture content of grain if the ambient air is used for natural air drying (NAD). The EMC of the air depends on the air’s temperature and relative humidity (RH) as well as the grain type. The EMC represents the moisture content that the grain will eventually equilibrate to if the air conditions remain constant for a length of time. Although air conditions are rarely constant for longer than an hour, the EMC information can still be used to determine the range of air temperatures and relative humidities that will achieve drying

Grain Drying Tips

WHAT IS THE DIFFERENCE BETWEEN AERATION, NATURAL AIR DRYING, AND GRAIN DRYING WITH A SUPPLEMENTAL HEATER?

Aeration is used to control and provide uniform temperature for a grain mass. Natural air drying is generally used for farm bins and is a method of drying grain without using supplemental heat and is recommended at 1cfm (13.4L/s) per bushel of grain. Grain drying refers to adding supplemental heat to lower the moisture content of a grain mass at a flow rate of greater than 1cfm(13.4L/s) per bushel of grain. All three methods will help extend storage life for grain and prevent spoilage.